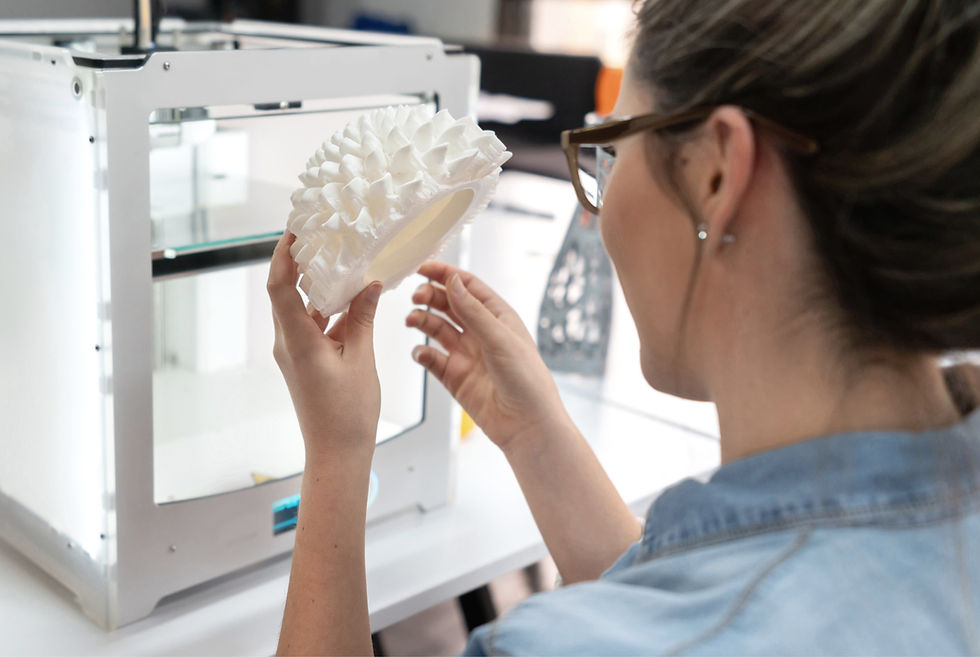

Imagine your equipment breaks down, and the replacement part you need is on backorder for weeks or, even worse, discontinued. Now, picture a world where you can have that part custom-made and ready in just a day or two. That is the power of on-demand 3D printing, and it’s transforming how businesses, manufacturers, and individual consumers manage repairs.

This isn’t just a futuristic concept—it’s happening now. Small but innovative 3D printing shops are helping businesses and individuals obtain high-quality replacement parts without the long waits, high costs, or international shipping frustrations. In fact, the global 3D printing market is expected to grow to $70 billion by 2027, a clear indicator of its rising importance in manufacturing.

Why On-Demand 3D Printing is Taking Off

3D printing has been around for some time, but recent advancements have made it faster, more precise, and practical for everyday use.

Speed

Traditional manufacturing can take weeks. In contrast, 3D printing often delivers parts in days or even hours. For instance, companies that previously spent 30 days waiting for parts can now get them in just 3 days. This efficiency can be a lifesaver for industries that require immediate solutions.

Customization

Need a unique part that’s no longer available? No problem—3D printing can recreate almost anything. For example, a restaurant might need a special utensil that is no longer manufactured. With 3D printing, they can have a replica made in just a few hours, keeping their operations running smoothly.

Lower Costs

Without the need for costly molds or mass production, businesses only print what they need when they need it. This not only saves on production costs but also reduces waste. For example, a study showed that companies using 3D printing reduced their inventory costs by as much as 50%.

What’s Driving the Future of 3D Printing?

Technology is advancing quickly, and 3D printing is evolving alongside it. Here are a few key trends that are making this industry increasingly exciting:

Stronger, More Durable Materials

Advancements in materials science mean that parts created using 3D printing are now made from industrial-grade plastics and metals, providing durability and strength. For instance, aerospace companies are utilizing titanium for parts, improving performance and safety.

AI-Powered Design

Smart software is optimizing prints for better performance and less waste. For example, machine learning can analyze and refine designs, resulting in parts that are not only more efficient but also lower in cost. Companies have reported up to a 20% reduction in material costs due to these AI advancements.

Multi-Material Printing

Imagine a single print that combines different materials for enhanced functionality. For example, a 3D print may layer silicone over rigid plastic to create a component that is both strong and flexible. This innovation opens up new creative avenues for product design.

Local Manufacturing Networks

More small businesses are emerging, making high-quality 3D printing accessible in various communities. This local approach means that parts are made closer to where they’re used, drastically lowering shipping costs and delivery times. For instance, a company in Portland can produce parts for a business across town, cutting down delivery from up to a week to just a few hours.

How 3D Printing is Helping Businesses and Consumers

On-demand 3D printing isn’t just a tech trend; it’s a necessary tool for both businesses and consumers.

Rapid Prototyping

Companies can quickly produce prototypes, allowing them to test designs without the lengthy wait times associated with traditional methods. For example, startups can now test five different prototypes within a week instead of waiting several months for traditional manufacturing, accelerating their go-to-market strategy.

Custom Solutions

Businesses grappling with unique challenges can order customized components designed for their specific needs. This agility gives small enterprises a competitive edge. A local bike shop might use 3D printing to create custom brackets tailored for specific models, enhancing their service offerings.

Eco-Friendly Production

On-demand 3D printing cuts down on waste by producing items as needed. This eco-friendly approach resonates with today's consumers, who are increasingly conscious of their environmental footprint. An environmental study found that on-demand printing can lower carbon emissions by as much as 40% compared to traditional manufacturing.

Community Engagement

Local 3D print shops foster a sense of community. They provide opportunities for individuals to learn and collaborate, share ideas, and innovate together. Participating in workshops can spark creativity and inspire new projects within the community.

The Impact on Industries

Almost every industry stands to gain from the rise of on-demand 3D printing. Let's take a closer look at a few sectors already experiencing this shift:

Healthcare

3D printing is transforming healthcare, from custom prosthetics to surgical tools. For example, a custom prosthetic leg can be made to fit a patient perfectly in just a few hours, improving the quality of care. Hospitals are embracing this technology, with 3D-printed medical devices expected to reach $6 billion by 2025.

Automotive

Car manufacturers can now produce rare or custom parts without maintaining extensive inventories. This flexibility saves time and improves customer satisfaction. For instance, manufacturers can speed up the replacement of critical car components, reducing customer wait times from weeks to just days.

Aerospace

In the aerospace sector, precision is crucial. On-demand 3D printing ensures that even the most intricate components are produced to the highest standards. For example, major airlines are using 3D printing to create lightweight components that improve fuel efficiency, saving an estimated $3 million per aircraft annually.

Looking Ahead: The Challenges and Opportunities

While the future of on-demand 3D printing appears bright, challenges remain.

Quality Control

Ensuring consistent quality in 3D-printed parts is essential. Though advancements are increasing, quality control remains a challenge that the industry must address continuously.

Regulatory Considerations

As 3D printing becomes more prevalent, regulations must evolve to keep pace. This complex issue is crucial to ensure safety and reliability as the technology spreads across various sectors.

Public Perception

Educating the public about the benefits of 3D printing is key to normalizing its use. Growing awareness can drive demand for local 3D print shops, further integrating this technology into everyday life.

Embracing the Future of 3D Printing

The future of on-demand 3D printing is reshaping how we think about manufacturing and repairs. With faster turnaround times, customized solutions, and significant cost savings, it’s clear that this technology is here to stay. Whether you're a business seeking to streamline operations or a consumer looking for unique solutions, the possibilities are truly limitless.

As technology continues to advance, we can expect even more exciting innovations that make 3D printing smarter, faster, and more affordable. Embrace this transformational technology and explore how it can change your world!

Comentários